In the relentless race to boost productivity and cut costs, the manufacturing industry often faces a crucial dilemma: how to balance efficiency with ethical integrity. Can companies truly streamline operations without compromising on their values? As the global market grows more competitive and consumers become more conscious of corporate practices, the answer to this question is more important than ever.

Imagine a world where every product is made not only swiftly and cost-effectively but also sustainably and ethically. This vision is not a distant dream but an achievable reality. In this article, we delve into the best practices that can help manufacturers achieve this balance, ensuring that their processes are both efficient and morally sound. Join us as we explore how integrating ethical principles into manufacturing can drive not only profitability but also long-term trust and loyalty from consumers and stakeholders alike.

Understanding the Need for Balance

It’s alarming to note that less than 2% of clothing workers earn a living wage, leaving an estimated 98% of 75 million clothing factory workers (Source: Fashion United) trapped in systemic poverty, unable to meet their basic needs (Source: The True Cost).

Efficiency in manufacturing involves optimizing processes to reduce waste, lower costs, and improve production speed. However, without a strong ethical foundation, these efficiencies can come at a high cost, including environmental degradation, poor labor conditions, and compromised product quality. Ethical manufacturing, on the other hand, ensures fair treatment of workers, environmental responsibility, and high-quality outputs, but can be perceived as a hindrance to rapid efficiency gains. The challenge lies in integrating these two crucial aspects seamlessly.

Best Practices for Ethical and Efficient Manufacturing Process Management

Adopt a Holistic Approach to BPM

Achieving true efficiency means considering the entire lifecycle of a product. By adopting a holistic approach to Business Process Management (BPM), companies can optimize production while upholding ethical standards. This involves evaluating every step from raw material sourcing to end-of-life disposal, ensuring responsible and effective operations.

Implement Robust Compliance and Audit Mechanisms

Vigilance and transparency are key to maintaining ethical standards. Therefore, regular audits and compliance checks should be woven into the BPM framework, swiftly identifying and addressing any ethical lapses. Transparent reporting builds trust and accountability, reinforcing a foundation of integrity.

Leverage Technology for Transparency and Accountability

Blockchain and IoT are revolutionizing manufacturing transparency. Blockchain ensures material and product traceability, while IoT devices provide real-time monitoring of conditions. These technologies enhance transparency and accountability, guaranteeing compliance with ethical and regulatory standards.

Engage and Educate Employees

Employees are the guardians of ethical practices. Regular training on ethics and integrity empowers them to make informed decisions. An engaged workforce takes ownership of ethical issues, fostering a culture of integrity throughout the organization.

Integrate Lean Manufacturing with Ethical Practices

Lean manufacturing can boost efficiency without compromising ethics. By integrating ethical considerations into lean practices, companies ensure that waste reduction efforts are fair and responsible. This means optimizing staffing levels while maintaining fair labor practices, balancing efficiency with integrity.

Establish Clear Ethical Guidelines and Policies

Clear ethical guidelines are essential for guiding behavior in manufacturing. Well-defined policies covering labor practices, environmental impact, and quality standards ensure that employees, suppliers, and partners understand and adhere to ethical standards, creating a cohesive and responsible manufacturing environment.

Foster a Culture of Continuous Improvement

Ethical manufacturing is a continuous journey. Consequently, regularly updating processes to incorporate best practices and new technologies helps maintain a balance between efficiency and integrity. By fostering a culture of continuous improvement, companies can stay ahead of ethical challenges and ensure sustainable success.

Case Studies: Success Stories

Several companies have successfully balanced efficiency with ethical integrity, serving as models for the industry. For instance, Patagonia, a renowned outdoor clothing manufacturer, has integrated sustainability into its business model, from using recycled materials to ensuring fair labor practices. One of their tag lines is “Everything we make has an impact on the planet.” Their commitment to ethical manufacturing has not only enhanced their brand reputation but also driven customer loyalty and operational efficiencies.

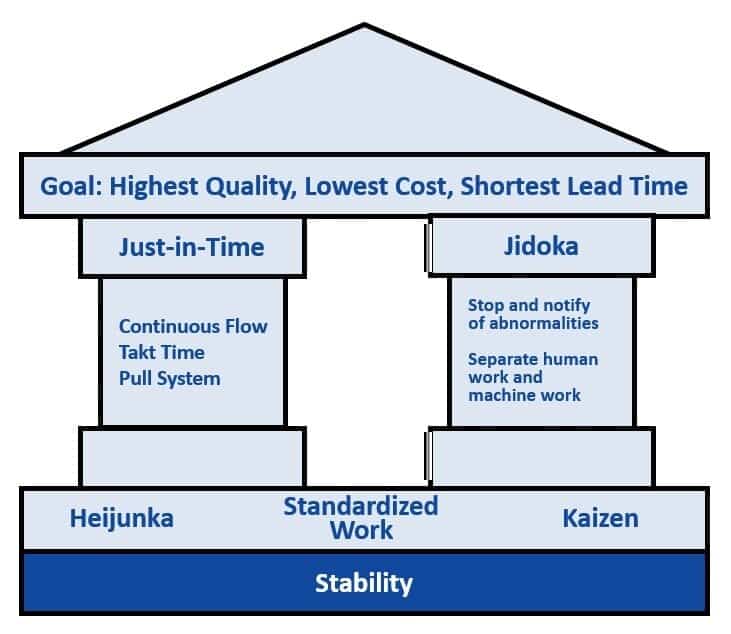

Another example is Toyota, whose lean manufacturing system, known as the Toyota Production System (TPS), incorporates respect for people and continuous improvement as core principles. This approach has enabled Toyota to maintain high efficiency levels while upholding strong ethical standards.

Conclusion

Balancing efficiency and integrity in manufacturing process management is not just a regulatory necessity but a strategic advantage. Companies that master this balance are better positioned to achieve sustainable growth, enhance their brand reputation, and build trust with consumers and stakeholders. By adopting holistic BPM practices, leveraging technology, engaging employees, and fostering a culture of continuous improvement, manufacturers can achieve the dual goals of operational efficiency and ethical integrity.

Ready to transform your manufacturing processes with efficiency and integrity? Discover how Cadynce BPM can streamline your operations. Contact us to get a demo!